By the late 60s Robin was working closely with Stokes hardening guns. Classic Case Colors LLC.

Tyler Gun Works Master Craftsman Of Color Case Work

Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade steel.

. This is the ONLY Gel Patina in This Build Your Own Kit That is NOT Optional. Color case parts with their subtle shades of blue gray and straw really give a gun a true custom look. However physics are physics so perhaps case color hardening finishes are still vulnerable to graying or require maintenance and or manufacturing using lacquer or other means.

Return shipping and insurance of firearm completed remain the responsibility of the customer. Ad Solve Your Thermal Processing Challenges. Improve The Wear Properties Of Your Parts With Vacuum Carburizing.

Bone-meal preparation the arrangement of the components in the carbon pack the heat cycle and the quench. It is heated to somewhere around 1200 to 1400 degrees and then quenched. Case Hardening of 16MnCr5.

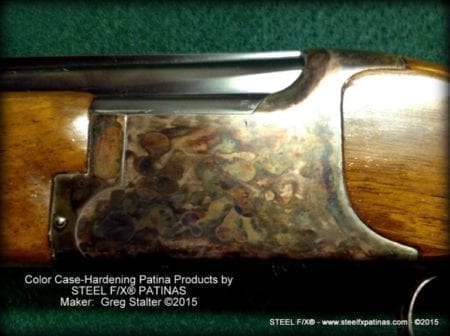

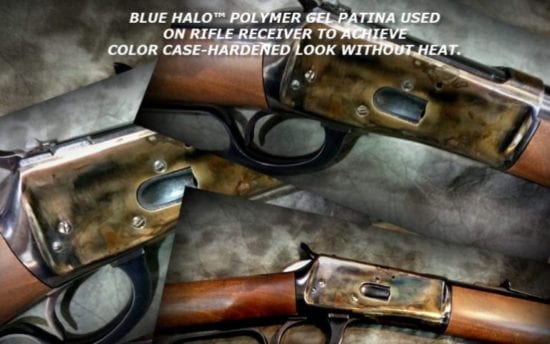

BLUE HALO Gel Patina is The Single Most Important Gel Patina for the Color Case-Hardening Look. For a modern firearm color case hardening can create a. Browse our list below to see which newly-manufactured firearms weve transformed with Turnbull Finished Services.

British Color Case Hardening 85 took him under his wing. Color case hardening is accomplished in one of two ways. It Will Produce a Range of Colors from Yellow-Gold to Grays Blue-Grays Various Shades of Blue.

I have no idea what it covers or if it is even any good its just something I ran across recently. The charge size is 8 tons. Industry leading metal treating.

Stock when though my bleaching process to take out all of the black stains recheckered and hand rubbed oil finish with open pore finish to match original finish. 1958 Browning A-5 20ga. Which is cost and effort related and which Cz does not employ at their price point.

Open key trigger guard forend. WE ARE A FEDERALLY LICENSED FIREARMS MANUFACTURING AND REPAIR FACILITY LOCATED IN SCENIC NORTHERN IDAHO SPECIALIZING IN THE FAITHFUL RESTORATION OF GENUINE BONE CHARCOAL COLOR CASE HARDENING RUST BLUING AND HAND RUBBED OIL FINISHES ON VINTAGE AND ANTIQUE SPORTING ARMS. Afterwards the parts were removed from the furnace and quenched.

Contracted at the cost of 210 for each 100 value. The process results in a marbleized coloring of the parts and provides a thin hardened layer of steel while preserving a softer steel core. Some of the classic shotgun with case harden were.

The first thing Ted taught me. Action hand 6 holes welded and all engraving was re-cut. The total costs are 1353 and the process takes 46 hours.

Traditional color case hardening consists of four major steps. Single action revolvers and shot guns are very popular to color case harden. Ad Higher reliability case hardening.

What little I know about case coloring hardening is that the actual colors are a desirable by-product of the real intent. Initially it required the bone charcoal to be warmed up to a specific temperature. This process is one of the earliest ways of hardening the steel even of the lower grade.

It is a process of heat treating mainly. Shotgun was restored with original slow rust blue. The traditional method and the most durable is to heat the metal in a container with both hardwood charcoal and bone charcoal.

James Purdey Sons Shotguns Parker Shotguns LC. Widest range of metal coatings. We use the traditional wood and bone charcoal method of color case hardening.

Originally this process used bone charcoal heated to an exact temperature. Contracted at the cost of 210 for each 100 value. For each job at no extra cost the action trigger guard floor plate bolt shrould safety trigger and bolt release are case colored.

4751-Shotgun small parts. Wyoming Armory Precision Firearms in Cody Wyoming offers a full range of gunsmithing services for all types of firearms from flintlock and percussion rifles and pistols to single shot Winchester 1885s shotguns bolt action rifles revolvers and modern semi-automatic pistols and semi-automatic rifles. Wyoming Armory is a custom gunsmithing shop where we build custom firearms but one of our specialities is tradional bone charcoal color case hardening.

The other method to accomplish a brighter set of colors but a less durable finish is. Rating Required Select Rating 1 star worst 2 stars 3 stars average 4 stars 5 stars best Name. Trigger was re-gold plated.

Smith shotguns Winchester model 21 Shotguns Farmers Shotguns AH Fox. I will also do butt plates and. No reviews yet Write a Review.

7 inches with a weight of approximately 3 kg 66 pounds. From the earliest guns that were made in the 10th century til the mid-late 1800s firearms were made of soft materials out of necessity. Perma ColorCase Coloring Kit.

At last a convenient easy-to-use process to help the gunsmith create beautiful genuine color case hardening. The American Custom Gunmakers Guild has a video for sale on their website concerning Color Case Hardening and Nitre Blueing. 1958 Browning A-5 20 ga.

Of course the earliest ones were made out of bamboo. Many old guns have faded color case hardening. The color case hardening is also known as case hardening case color hardening and surface hardening.

275 1-Sidelock side by side receiver. Bone charcoal color case hardening charcoal bluing rust bluing hand-rubbed oil wood finishes nitre bluing engraving all period-correct and worthy of heirloom status. All gunsmithing services are performed by.

Color Case hardening is getting very popular. I think that the whole purpose of carborizing the metal is to surface harden it for better wear and durability properties. And Any Size You Choose is15 Off.

Please email Howell Arms so we can provide you with a preliminary quote prior to shipping. Advanced Expertise And World-Class Equipment. Perma ColorCase Coloring Kit.

The most flexible production capacity. 1Prices-Superposed or side by side shotgun receiver. Click to see full answer.

Its a subject for another post but Id buy another Sharp-tail in a heartbeat. Color case hardening sometimes referred to as case-hardening case color hardening or surface hardening is a heat treating process and one of the earliest ways of hardening lower-grade steel. We use the traditional wood and bone charcoal method of color case hardening.

Mauser 93 95 96 98 Color Case Hardening Osre Old South Restoration

Color Case Hardening Patina Kit

Is Case Hardening Supposed To Uh Come Off R Guns

Color Case Hardening Turnbull Restoration

The Story Of Bobby Tyler And What Makes His Casehardening So Special Ballistic Magazine

The Story Of Bobby Tyler And What Makes His Casehardening So Special Ballistic Magazine

Color Case Hardening Patina Kit

The Story Of Bobby Tyler And What Makes His Casehardening So Special Ballistic Magazine

Ruger Vaquero Revolver With Turnbull Color Case Hardening Sold Turnbull Restoration

Color Case Hardening Patina Kit

How To Do Color Case Hardening The Hobby Machinist

Who Is Recomended For Color Case Hardening An 1894 Marlin Firearms Forum

![]()

Color Case Hardening Lohman Gunsmith Houston Tx

Color Case Hardening Patina Kit

Tyler Gun Works Master Craftsman Of Color Case Work

Color Case Hardening Patina Kit

Color Case Hardening 1911forum

Feature Suggestion Cosmetic Color Case Hardening R Reddeadredemption

The Story Of Bobby Tyler And What Makes His Casehardening So Special Ballistic Magazine